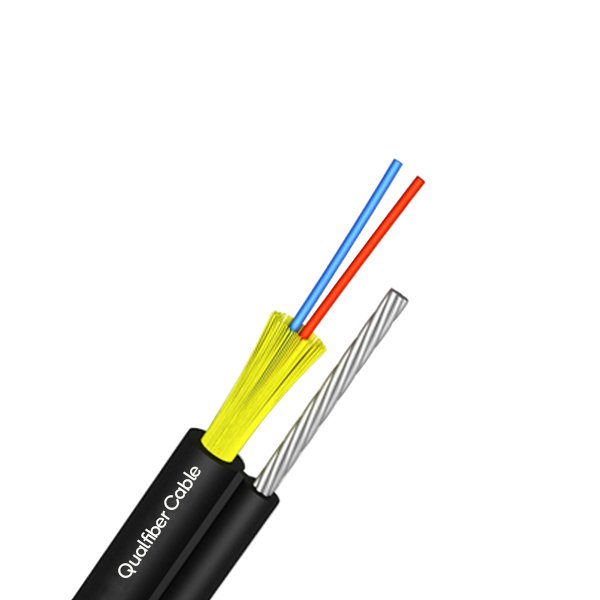

GYFTA (non-metallic strengthening member, loose tube stranded filling type, aluminum-polyethylene bonded sheathed outdoor optical fiber cable for communication) The structure of the optical cable is to sheath single-mode or multi-mode optical fiber into a high-modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a non-metallic reinforced core (FRP). For certain fiber optic cables, a layer of polyethylene (PE) is extruded outside the non-metallic reinforced core or a non-metallic reinforced yarn is added to the cable core. line. The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core. The gaps in the cable core are filled with water-blocking compounds, and the plastic coated aluminum tape is longitudinally wrapped with a polyethylene sheath.

Color:

Discription

The GYFTA fiber optic cable is a non-metallic reinforcing member, a loose-jacketed strand-filling type, and an aluminum-polyethylene sheathed communication outdoor optical cable.

Features

Full-section water-blocking structure, double-coated aluminum strip longitudinal package, ensuring good water and moisture resistance

Loose sleeve filled with special ointment for critical fiber protection

High modulus glass fiber reinforced plastic rod (FRP) center reinforcing member .

Polyethylene sheath makes the cable have good UV resistance .

Product life more than 30 years .

Technical Data Sheet

Environmental performance of optical cable

| Pilot projects | experiment method |

| Temperature cycle test | a. Temperature steps: +20 ℃ , -40 ℃ , +70 ℃ , +20 ℃ ;

b. Holding time: 12 hours per step for single-sheathed optical cable , 24 hours per step for double-sheathed optical cable , number of cycles: 2 cycles; |

| Water seepage test | The water permeability of the finished optical cable should meet the requirements of IEC60794-1-F5B , and it should be carried out on the full section of the optical cable, meeting the requirements of 1m water column, 1m optical cable, and no water seepage for 8 hours. |

| Optical cable outer sheath

Insulation resistance |

An outer cable sheath insulation resistance ( armor layer between the inner and the outer sheath of the earth ) , soaking in the cable 24 hours after the test, of not less than 2000 M • km (DC 500 V test). |

| Dielectric strength | Between the inner armor layer of the outer sheath and the earth: test after the optical cable is immersed in water for 24 hours, not less than DC 15 kV for 2 minutes. For double-sheathed optical cables, it is required that between the outer sheath and the inner armor and the metal reinforced core: no less than DC 20 kV for 5 seconds, in line with the requirements of GB/T 1408.1-2006 . |

| Drip test | Under the environmental conditions of 70 ℃ ( 24h ), the optical cable should not drip out of filling compound and coating compound. |

package

| Number of cores | Loading length km | Net weight (approximate)

kg |

Gross weight (approximate)

kg |

Disk size

cm |

| 2-30 | 2 | 150 | 195 | 9 0× 9 0× 7 0 |

| 3 | 225 | 280 | 10 0× 10 0× 7 0 | |

| 4 | 300 | 360 | 11 0× 11 0× 7 0 | |

| 32-60 | 2 | 175 | 230 | 10 0× 10 0× 7 0 |

| 3 | 265 | 325 | 11 0× 11 0× 7 0 | |

| 4 | 350 | 425 | 125 × 125 × 7 0 | |

| 60-72 | 2 | 200 | 255 | 10 0× 10 0× 7 0 |

| 3 | 300 | 360 | 11 0× 11 0× 7 0 | |

| 4 | 400 | 475 | 125 × 125 × 7 0 | |

| 74-96 | 2 | 270 | 325 | 100×100×70 |

| 3 | 405 | 480 | 125 × 125 × 7 0 | |

| 4 | 540 | 630 | 125 × 125 × 9 0 | |

| 98-120 | 2 | 330 | 405 | 125 × 125 × 7 0 |

| 3 | 495 | 585 | 125 × 125 × 9 0 | |

| 122-144 | 2 | 400 | 510 | 140 × 140 × 85 |

| 3 | 600 | 730 | 160 × 160 × 105 | |

| Packing | Use wooden plate (iron wooden plate), plate nail certificate, factory inspection report

(Or according to customer requirements) |

|||

Fiber Color

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color |  |

|

|

|

|

|

Tube Color

| No. | 1 | 2 | 3 | 4 |

| Color |  |

|

|

|

Mechanical and environment performance

Package

Packing material: Wooden drum.

Packing length: 2km per drum.