Optic Fiber Cable Laying Solution

Qualfiber Technology's fiber optic cable widely applied in different kinds of environments. In order to adapt to the complex environment of various ways of optic fiber cable laying, we self-developed many base materials, such as aramid yarn, HDPE sheath material, water-proof material, etc. Every drum of fiber optic cables have been rigorously tested of mechanical strength, the inner structure, and intercommunity.

1. According to the transmission performance, distance and use of different, cables can be divided into user cable, local cable, long-distance cable, and submarine cable.

2. According to the different types of optical fiber used in optical cable, the optical cable can be divided into single-mode optical cable and multi-mode optical cable.

3. According to the number of optical fiber core in optical cable, the optical cable can be divided into single-core optical cable, double-core optical cable, and so on.

4. According to the different reinforcement configuration method, the cable can be divided into central strengthening member cable, dispersed strengthening member cable, sheath strengthening member cable and comprehensive outer sheath cable.

5 according to the transmission conductor, medium condition, the optical cable can be divided into no metal optical cable, ordinary optical cable, integrated optical cable (mainly used for railway special network communication lines).

6. According to the different laying methods, the optical cable can be divided into pipeline optical cable, directly buried optical cable, aerial optical cable, and underwater optical cable.

7. According to the different structures, the optical cable can be divided into flat structure optical cable, stranded optical cable, skeleton optical cable, armored optical cable, and high-density user optical cable.

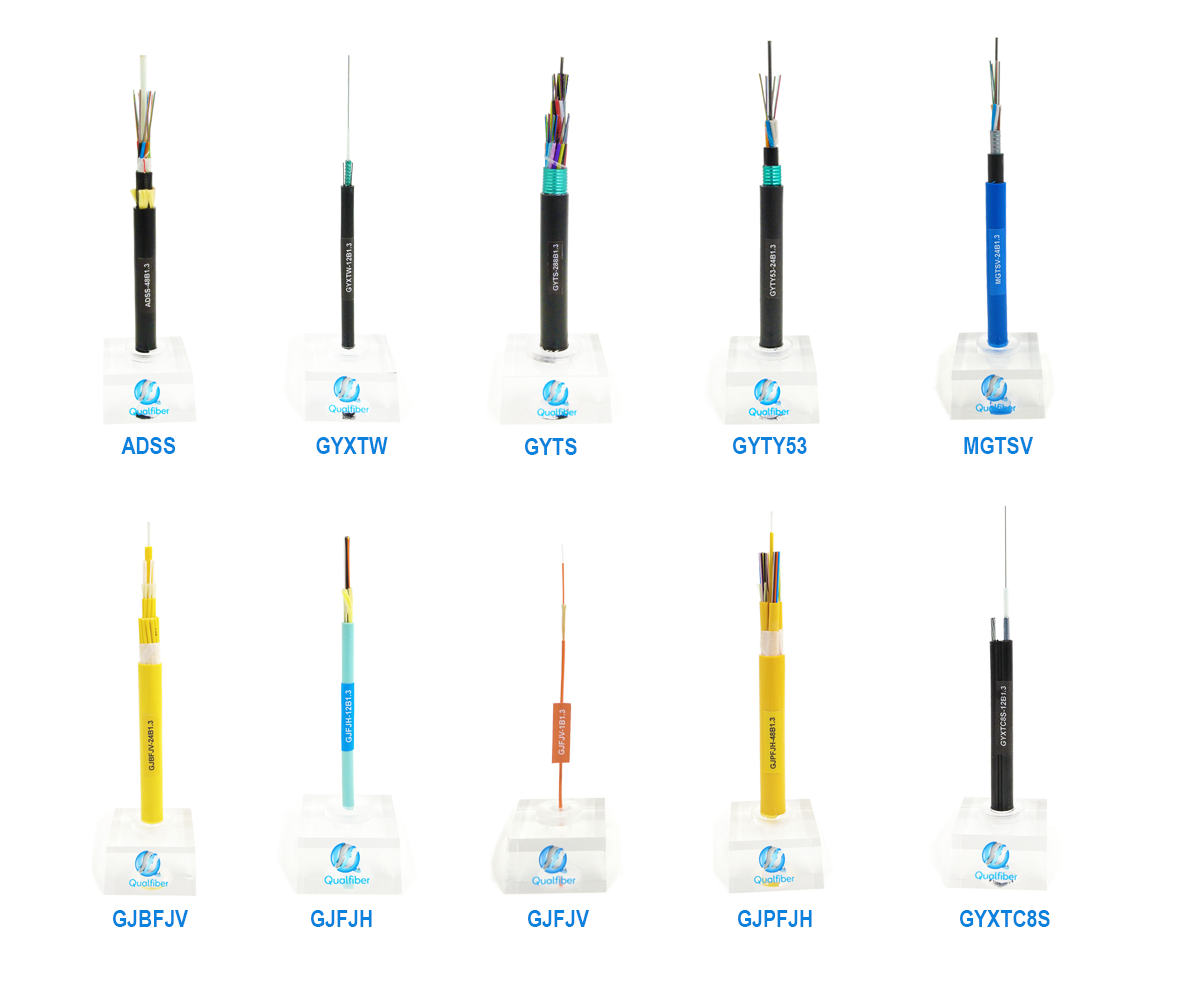

Common types of fiber optic cable

1. Stranded Loose Tube Cable

| GYTA, GYTS,GYFTY, GYHTY

GYFTA |

Gel filling | Flame-retardantAnti-rodent and anti-termite

Colored strip |

| GYTY53, GYTA53GYFTY53, GYFTA53

GYTA53+33 |

Gel fillingDry cores

Dry tubes& cores |

Flame-retardantAnti-rodent and anti-termite

Colored strip |

2. Central Tube Cable

| GYXTW, GYXTW53GYXY, GYFXY | Gel filling | Flame-retardantAnti-rodent and anti-termite |

3. Special Cable

| MGTS, MGXTW, GYTC8AGYDTA | Gel filling | Colored strip |

| GYFTZA53, GYTZA53GYTZS, GYXTZW, ADSS | Gel filling | Anti-tracking100m above span distance |

Outdoor Optical Cable

Stranded Loose Tube Non-armored Cable (GYTA)

The fibers, 250pm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of the core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core, which is filled with the filling compound to protect it from water ingress. Then, the cable is completed with a PE sheath.

Characteristics

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube jelly compound ensure a critical protection of fiber

Designed compact structure is good at preventing loose tubes from shrinking

PE sheath protects the cable from ultraviolet light

Stranded Loose Tube Light-armored Cable (GYTS)

The fibers, 250m, are positioned in a loose tube made of a high modulus plastic. The tubes are laid with a water-resistant Hing compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high ber count, locates in the center of the core as a metallic strength member. Tubes (and Ilers) are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core, which is laid with the jelly compound to protect it from water ingress. Then, the cable is completed with a PE sheath.

Characteristics

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube jelly compound ensure a critical protection of fiber

Designed compact structure is good at preventing loose tubes from shrinking

PE sheath protects the cable from ultraviolet light

Crush resistance and flexibility

Stranded Loose Tube Non-metallic Strength Member Non-armored Cable (GYFTA)

The bers, 250m, are positioned in a loose tube made of a high modulus plastic. The tubes are lied with a water-resistant Hing compound. A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member. The tubes (and Ilers) are stranded around the strength member into a compact and circular core. After an Aluminum Polyethylene Laminate (APL) moisture barrier is applied around the cable core, the cable is completed with a PE sheath.

Characteristics

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube jelly compound ensure a critical protection of fiber

Designed compact structure is good at preventing loose tubes from shrinking

PE sheath protects the cable from ultraviolet light

Crush resistance and flexibility

Stranded Loose Tube Armored Cable(GYTA53/GYTS53/GYTY53)

The fibers, 250m, are positioned in a loose tube made of a high modulus plastic. The tubes are laid with a water-resistant Hing compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high ber count, locates in the center of the core as a metallic strength member. Tubes (and Ilers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core, which is lied with the Hing compound to protect it from water ingress. Then, the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Characteristics

Full-section water blocking structure to ensure good water blocking performance

The loose tube is filled with special grease to protect the optical fiber critically

The polyethylene sheath ensures that the optical cable has good UV resistance

The aluminum-plastic composite tape ensures that the optical cable has good moisture resistance

Tensile performance and compression performance of steel-plastic composite tape armored reinforced optical cable

Product service life is more than 30 years

Unitube Light-armored Cable(GYXTW/GYXTW53)

Outdoor central loose tube optic fiber cable. GYXTW is an outdoor communication optical cable with a metal strength member of the central tube jelly-filled structure with corrugated steel-polyethylene laminated sheath, consisting of the central loose tube, two paralleled steel wire strength members, and PE outer sheath.

Characteristics

Full cross-section water-blocking structure to ensure good water blocking and moisture resistance.

The loose tube is filled with special ointment for key fiber protection.

Two parallel round steel wires are resistant to tensile and lateral pressure.

Small cable diameter, lightweight, and excellent bending properties.

The loose tube is in the physical center of fiber optic cable, easy for installation and operation.

Product life of 30 years.

Loose Tube Mining Flame-retardant Cable(MGTS/MGTSV)

The MGTSV optical cable is a flame-retardant communication optical cable for mines with metal strengthening members, loose tube stranded and filled, steel-polyethylene inner sheath, low carbon steel wire wrapping, and flame-retardant CMR sheath.

Characteristics

Full-section water-blocking structure, double-sided film-coated steel strip longitudinal wrapping, to ensure good water blocking performance and resistance to lateral pressure

The loose tube is filled with special grease to protect the optical fiber critically

High modulus and corrosion resistance of phosphating steel wire center reinforcement

CMR jacket makes the optical cable have good flame retardant performance

Low carbon steel wire wrapped to strengthen the tensile strength and lateral compressive strength of optical cable

Product service life is more than 30 years

Figure 8 Cable(GYTC8A /GYTC8S/GYXTC8S)

The structure of the GYTC8S optical cable is to sheath 250μm optical fiber into a loose tube made of high modulus material, and the loose tube is filled with a waterproof compound. The center of the cable core is a metal reinforced core. The loose tube (and filler rope) is twisted around the central reinforced core to form a compact and circular cable core. The cable core is longitudinally wrapped with a layer of plastic-coated steel tape and integrated with the steel wire strands. Into a figure 8 polyethylene sheath

Characteristics

Full-section water-blocking structure, double-sided film-coated aluminum tape longitudinally wrapped to ensure good water-blocking and moisture-proof performance

The loose tube is filled with special grease to protect the optical fiber critically

High modulus and corrosion resistance of phosphating steel wire center reinforcement

The figure-eight self-supporting structure has high tensile strength, which is convenient for overhead laying and low installation cost

The polyethylene sheath makes the optical cable have good UV resistance

Product service life is more than 30 years

Optic Electric Composite Cable(GYTS+2x2.5/GDVV+2x4/GYTA+2x4/GYTS+2x4)

The fibers,250m, are positioned in a loose tube made of a high modulus plastic The tubes are lined with a water-resistant Hing compound. The cable core is FRP or metallic strength member some structures need to add PE as a bedding layer in the strength member). Electric wires and tubes (and Ilers) are stranded around the strength member into a compact and circular cable core. The cable core is lied with the Hing compound to protect it from water ingress. After two sides of PSP are longitudinally applied over the inner sheath, the cable is completed with PE or LSZH outer sheath.

Characteristics

Electricity lines, telephone lines, television lines, network lines, monitor lines, and data lines are multi-one networks, saves costs

Good mechanical and temperature performance

Opto and electricity integrated, fully save pipeline resources

Electric and optical cable maintain relatively independent structure, easy to import, export and link when installation

Cable diameter and bending radius are small, freely install in small space and compatible with optical signal and electric energy transmission

operating temperature range and construction temperature range