Part number definition

| GY | Communication room (field) outdoor optical cable | none | no reinforcement | B | Flat shape | A | Aluminum-polyethylene bonded sheath | 5 | Corrugated steel belt | Codename | Coating or jacket code | A1a | IEC and GB/T | G.651 | ||||||

| GH | Submarine Optical Cable for Communication | F | Non-metallic reinforcement | C | Self-supporting structure | G | Steel sheath | 44 | Double thick round steel wire | 1 | Fiber cover | A1b | IEC and GB/T | G.651 | ||||||

| GJ | Optical cable in communication room (office) | G | Metal heavy reinforcement | D | Fiber ribbon structure | L | Aluminum sheath | 4 | Single thick round steel wire | 2 | Polyethylene protection tube | A1c | IEC and GB/T | G.651 | ||||||

| GR | Flexible Optical Cable for Communication | H | Non-metallic heavy-duty reinforcement | E | Oval shape | Q | Lead sheath | 33 | Double thin round steel wire | 3 | Polyethylene sleeve | A1d | IEC and GB/T | G.651 | ||||||

| GS | Optical fiber cable in communication equipment | G | Skeleton trough structure | S | Steel-polyethylene bonded magnetic protection | 3 | Single thin round steel wire | 4 | Polyethylene sleeve and nylon sleeve | B1.1 (B1) | Non-dispersion shifted fiber | G652 | ||||||||

| GT | Special optical cable for communication | J | Fiber tight sleeve coating structure | U | Polyurethane sheath | 2 | Double steel belt | 5 | PVC sleeve | B1.2 | Cut-off wavelength shifted fiber | G654 | ||||||||

| GW | Metal-free optical cable for communication | R | Inflatable structure | V | PVC sheath | 0 | No armor layer | B1.3 | IEC and GB/T | G.652C | ||||||||||

| GM | Mobile optical cable for communication | T | Grease filled structure | W | Steel-polyethylene bonded sheath with parallel steel wires | B2 | Dispersion shift type optical cable | G653 | ||||||||||||

| X | Cable bundle tube (coating) structure | Y | Polyethylene sheath | B4 | Non-zero dispersion shifted fiber | G655 | ||||||||||||||

| Z | Flame retardant |

Product description

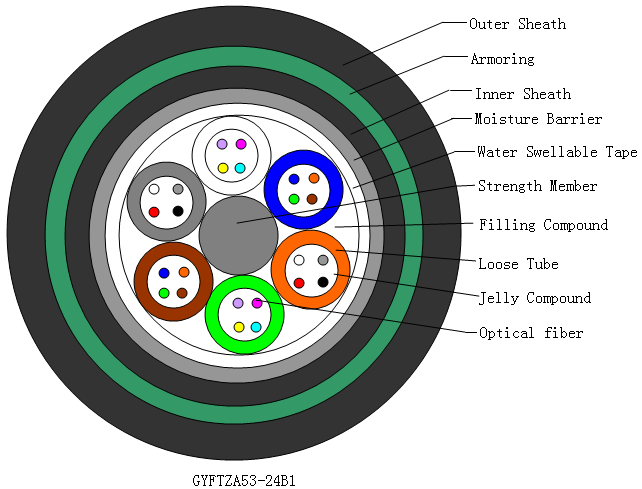

GYTZA53 (metal strengthening member, loose tube layer stranded filling type, aluminum-polyethylene bonded sheath, longitudinally wrapped corrugated steel tape armor, flame-retardant polyethylene sheath outdoor optical fiber cable for communication) The structure of the optical cable is a single-mode or multi-mode The optical fiber is sheathed in a loose tube filled with waterproof compound made of high modulus plastic. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The plastic-coated aluminum tape is longitudinally wrapped and then extruded with a polyethylene inner sheath, and the double-sided plastic-coated steel tape is longitudinally wrapped and then extruded with a flame-retardant polyethylene sheath.

Features

●Precise control of the excess length of the optical fiber ensures that the optical cable has good tensile performance and temperature characteristics

●PBT loose tube material has good hydrolysis resistance, and the tube is filled with special grease to protect the optical fiber

●Excellent pressure resistance

●Smooth outer sheath enables the optical cable to have a smaller coefficient of friction during installation

●The following measures are taken to ensure the waterproof performance of the optical cable: the loose tube is filled with special waterproof compounds; the cable core is completely filled; the moisture-proof layer of plastic-coated aluminum tape and steel tape

Applicable laying

●Directly buried and other places with flame retardant requirements

Structure

|

|

Technical Data

| Optical Fiber Type |

Sumitomo Pureband. G652D Without any joints along all cable length in one spool |

|

| Fiber grouping | Freely laid bunch of fiber inside tube. For fiber count is 12. | |

| Loose tube | 2.1 ± 0.1mm, PBT, when 12 fibers inside | |

| Center Strength member |

Steel wire |

|

| Armor |

Corrugated steel tape with overlap, covered with plastic layers on both sides |

|

| Minimal pull tension strength |

3000N |

|

| Minimal crush pressure |

3000N/100mm |

|

| Inner Jacket |

MDPE Thickness:1.0mm |

|

| Outer Jacket |

ZPE. Thickness:1.8mm |

|

| Minimal bending radius, n x Ø | Static |

12.5 |

| Dynamic |

25 |

|

| Temperature | Installation |

-40oC ~ 70oC |

| Operation/Storage |

-40oC ~ 70oC |

|

Post time: Feb-16-2021