The fibers, 250µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A Fiber Reinforced Plastic (FRP)/Steel wire locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. After the cable core is filled with the filling compound to protect it from water ingress, the cable is completed with a PE sheath

Color:

Description

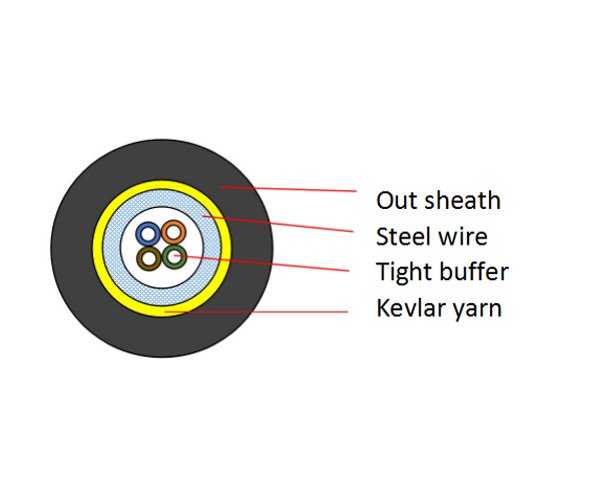

Cable construction

| Fiber count | 4F | ||||||

| Tight buffer | Diameter | 0.9mm | Material | PVC | |||

| Armor | Material | Spiral steel wire | Diameter | 3.0±0.1mm | |||

| Yarn | Material | Dupont kevlar yarn | |||||

| Out sheath | Material | LSZH | Color | Black | |||

| Diameter | 4.5±0.3mm | Thickness | 0.6±0.05mm | ||||

Cable mechanical and environment characteristics

| Tensile strength | Long term(N) | 100N | |||||

| Short term(N) | 300N | ||||||

| Crush load | Long term(N) | 300N/100mm | |||||

| Short term(N) | 1000N/100mm | ||||||

| Bending radius | Dynamic | 20D | |||||

| Static | 10D | ||||||

| Temperature | -20℃~+70℃ | ||||||

Fiber characteristics

| Fiber style | Unit | SM G652D | MM 50/125 | MM 62.5/125 | |||

| Condition | mm | 1310/1550 | 850/1300 | 850/1300 | |||

| Attenuation | dB/km | ≤0.4/0.3 | ≤3.0/1.5 | ≤3.0/1.5 | |||

| Cladding diameter | um | 125±1 | 125±1 | 125±1 | |||

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | |||

| Coating diameter | um | 242±7 | 242±7 | 242±7 | |||

Package

Packing material: Wooden drum.

Packing length: 2km per drum or customization.

Write your message here and send it to us