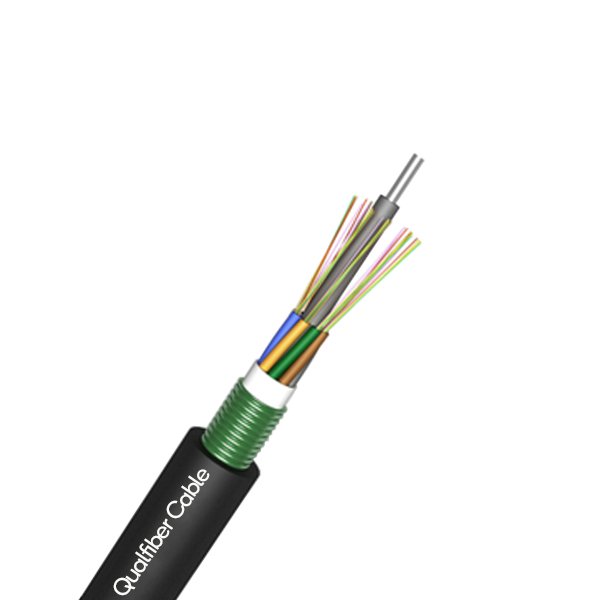

In the standard flame-resistant optical fiber cable for mine use, the fibers are positioned in a loose tube made of high modulus plastic. The tubes are filled with water-resistant filling compound. Two steel wires are used as central strength members. Between loose tube and sheath are filled with water proof non-woven fabrics of high density. At last, the cable is completed with a blue PVC sheath.

Color:

Features:

- Proper design and precise control of fiber excess in the loose tube render good tensile strength and temperature performance.

- The flame-resistant blue PVC sheath provides excellent effect of anti-flaming.

- Two parallel steel wires, steel-PE bonded sheath and PVC outer sheath offers good mechanical performance.

Applications: mainly used for transmission of voice, images and data in mine.

Environment temperature: - 40℃ ~ +60℃

Laying Mode: Aerial

Structural characteristics and the main performance parameters

| Model type MGXTSV | Specification | Outer diameter | weight | Tensile strength | Compressive strength | Bend radius | |||

| Long term | Short term | Long term | Short term | Long term | Short term | ||||

| 2 ~ 8 | 10.5mm | 120kg | ≧600N | ≧1500N | ≧300N | ≧1000N | 1m | 2m | |

| 10 ~ 12 | 10.5mm | 125kg | ≧600N | ≧1500N | ≧300N | ≧1000N | 1m | 2m | |

| Attenuation of single mode fibers | Attenuation of multi mode fibers | Performance of flame resistance | Density of smoke | ||

| 1310 | 1550 | 850 | 1300 | The bundle burning carbonized parts less than 2.5m | Light transmittance: 50% |

| 0.36db/km | 0.22db/km | 3.0db/km | 1.5db/km | ||

|

Use wooden disc (iron wooden disc), nail certificate, inspection report |

||||||

| Fiber cores |

2~8 |

10~12 |

2~8 |

10~12 |

2~8 |

10~12 |

| Plate length |

2km±1% |

3km±1% |

4km±1% |

|||

| Plate size |

100×100×70 cm |

110×110×70 cm |

125×125×70 cm |

|||

| N.W |

215 |

220 |

325 |

330 |

430 |

440 |

| G.W |

270 |

275 |

385 |

390 |

505 |

515 |

Write your message here and send it to us