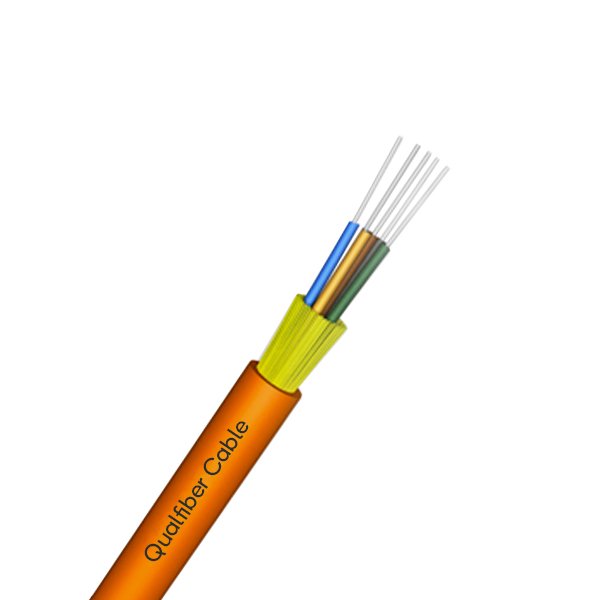

GYFTA53 (metal strengthening member, loose tube layer stranded filling type, aluminum-polyethylene bonded sheath, longitudinally wrapped corrugated steel tape armor, polyethylene sheathed outdoor optical cable for communication) The structure of the optical cable is a single-mode or multi-mode optical fiber jacket Into a loose tube made of high modulus plastic filled with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. Plastic-coated aluminum tape is longitudinally wrapped and then extruded with a layer of polyethylene inner sheath, double-sided plastic-coated steel tape is longitudinally wrapped and then extruded with a polyethylene sheath

Color:

説明

GYTA53 (metal strengthening member, loose tube layer stranded filling type, aluminum-polyethylene bonded sheath, longitudinally wrapped corrugated steel tape armor, polyethylene sheathed outdoor optical cable for communication) The structure of the optical cable is a single-mode or multi-mode optical fiber jacket Into a loose tube made of high modulus plastic filled with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. Plastic-coated aluminum tape is longitudinally wrapped and then extruded with a layer of polyethylene inner sheath, double-sided plastic-coated steel tape is longitudinally wrapped and then extruded with a polyethylene sheath

構造の詳細

| 繊維の数 | 6F | 12F | 24F | 36F | 48F | 72F | 96F | 144F |

| チューブ数 | 1 | 1 | 2 | 3 | 4 | 6 | 8 | 12 |

| チューブあたりの繊維 | 6 | 6 | 6 | 12 | 12 | 12 | 12 | 12 |

| フィラーロッド | 5 | 4 | 2 | 3 | 2 | 0 | 0 | 0 |

| チューブ径(±0.1mm) | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| 緩い管の厚さ (±0.05mm) |

0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| シース内径 (±0.2mm) |

9.2 | 9.2 | 9.2 | 9.2 | 9.2 | 9.2 | 10.8 | 13.2 |

| Thickness of inner diameter (±0.2mm) |

1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| 外径(±0.5mm) | 13.8 | 13.8 | 13.8 | 13.8 | 13.8 | 13.8 | 15.6 | 18.2 |

| 外径の厚さ (±0.2mm) |

1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.8 |

| ルーズチューブ | 素材 | PBT | 色 | 標準スペクトル | ||||

| フィラーロッド | 素材 | PP | 色 | ナチュラル | ||||

| セントラルストレングスメンバー | 素材 | FRP | 直径 | 2.0mm±0.1mm | ||||

| 水焼却システム | 素材 | 止水テープ | ||||||

| Inner armor | 素材 | アルミテープ | ||||||

| インナーシース | 素材 | PE | 色 | ブラック | ||||

| リップコード | 数量 | 2枚 | 色 | 白い | ||||

| Outer armor | 素材 | 段ボール鋼テープ | ||||||

| アウターシース | 素材 | PE | 色 | ブラック | ||||

ファイバーカラー

| 番号。 | 1 | 2 | 3 | 4 | 5 | 6 |

| 色 |  |

|

|

|

|

|

| 番号。 | 7 | 8 | 9 | 10 | 11 | 12 |

| 色 |  |

|

|

|

|

|

チューブカラー

| 番号。 | 1 | 2 | 3 | 4 | 5 | 6 |

| 色 |  |

|

|

|

|

|

| 番号。 | 7 | 8 | 9 | 10 | 11 | 12 |

| 色 |  |

|

|

|

|

|

機械的および環境性能

| 抗張力 | 長期(N) | 1000N | ||||||

| 短期(N) | 3000N | |||||||

| クラッシュ荷重 | 長期 | 3000N / 100mm | ||||||

| 短期 | 1000N / 100mm | |||||||

| 曲げ半径 | 動的 | 20D | ||||||

| 静的 | 10D | |||||||

| 設置温度 | -10℃〜+ 60℃ | |||||||

| 保存温度 | -40℃〜+ 70℃ | |||||||

ファイバー性能

| ファイバースタイル | 単位 | SM G652D | MM 50/125 | MM 62.5 / 125 | ||||

| 状態 | んん | 1310/1550 | 850/1300 | 850/1300 | ||||

| 減衰 | dB / km | ≤0.36/0.22 | ≤3.0/ 1.0 | ≤3.0/ 1.0 | ||||

| クラッド径 | ええと | 125±1 | 125±1 | 125±1 | ||||

| 非円形のクラッド | % | ≦1.0 | ≦1.0 | ≦1.0 | ||||

| コーティング径 | ええと | 242±7 | 242±7 | 242±7 | ||||

パッケージ

梱包材:木製ドラム。

Packing length: 2km per drum.

Write your message here and send it to us