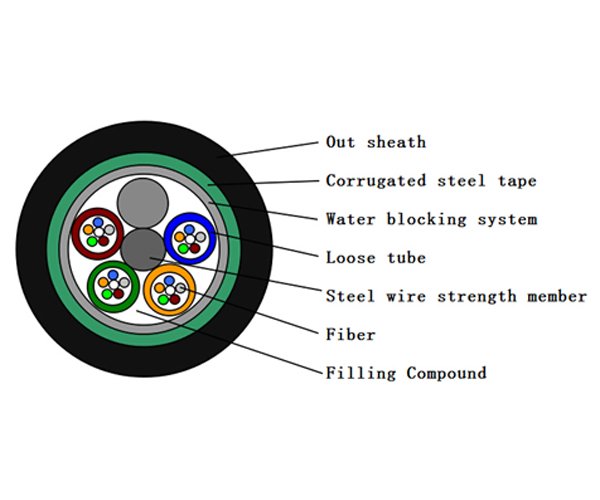

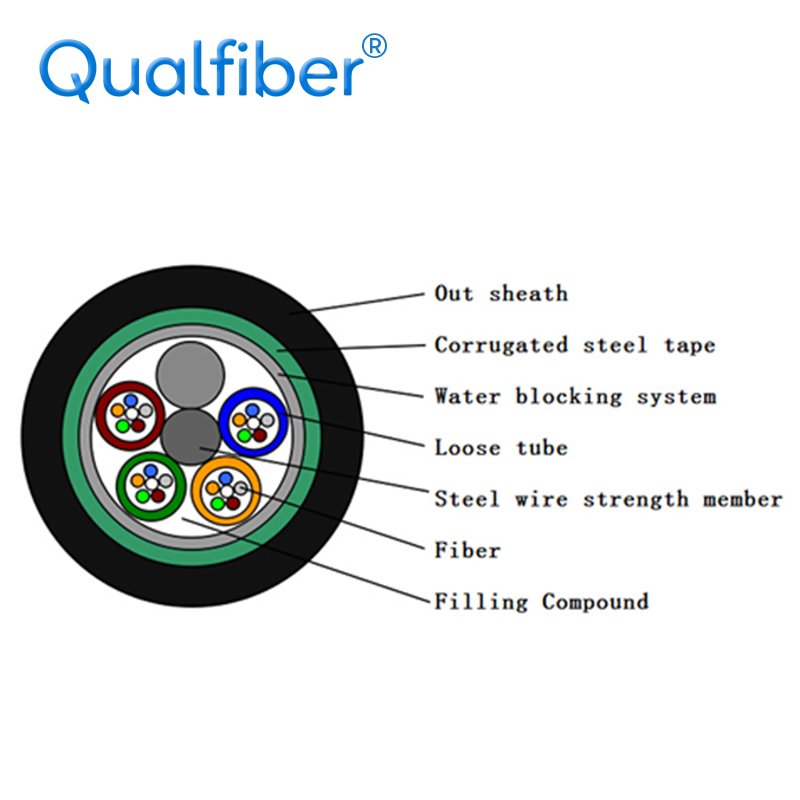

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Color:

Description

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Cable construction

| Number of fiber | 2~144 F | |||||||

| Moisture Barrier | Water blocking system | |||||||

| Central strength member | Material | Steel wire/FRP/FRP with PE cover | ||||||

| size | 1.5mm~2.0mm | |||||||

| Loose tube | material | PBT | ||||||

| diameter | Ф2.2(outer/inner) | |||||||

| Tube-filling | Tube filling compound | |||||||

| Armoring | Material | Corrugated steel tape | ||||||

| Outer sheath | material | PE, HDPE | ||||||

| diameter | 1.70±0.2mm | |||||||

Fiber Color

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color |  |

|

|

|

|

|

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color |  |

|

|

|

|

|

Tube Color

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color |  |

|

|

|

|

|

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color |  |

|

|

|

|

|

Cable Mechanical characteristic

| core | Cable diameter | weight | |||||

| 2 cores to 60 cores | 10.0±0.3mm | 115±5kg/km | |||||

| 72 cores | 10.5±0.3mm | 120±5kg/km | |||||

| 96 cores | 12.5±0.3mm | 180±5kg/km | |||||

| 144 cores | 14.5±0.3mm | 245±5kg/km | |||||

| Min Bending Radius(mm) | Long term | 10D | |||||

| Min Bending Radius(mm) |

Short term | 20D | |||||

| Min allowable Tensile Strength(N) |

Long term | 600 | |||||

| Min allowable Tensile Strength(N) |

Short term | 1500 | |||||

| Crush Load (N/100mm) | Long term | 300 | |||||

| Crush Load (N/100mm) | short term | 1000 | |||||

| Operation temperature (℃) |

-40+70 | ||||||

| Installation temperature(℃) |

-20+60 | ||||||

Fiber characteristic

| Fiber style | Unit | SM G652 |

SM G652D |

MM 50/125 |

MM 62.5/125 |

MM OM3-300 |

|

| condition | nm | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| attenuation | dB/km | ≤ | ≤ | ≤ | ≤3.0/1.0 | ≤3.0/1.0 | |

| 0.36/0.23 | 0.34/0.22 | 3.0/1.0 | —- | —- | |||

| Dispersion | 1550nm | Ps/(nm*km) | —- | ≤18 | —- | —- | Dispersion |

| 1625nm | Ps/(nm*km) | —- | ≤22 | —- | —- | ||

| Bandwith | 850nm | MHZ.KM | —- | —- | ≧400 | ≧160 | Bandwith |

| 1300nm | MHZ.KM | —- | —- | ≧800 | ≧500 | ||

| Zero dispersion wavelength | nm | 1300-1324 | ≧1302, ≤1322 |

—- | —- | ≧ 1295, ≤1320 |

|

| Zero dispersion slope | nm | ≤0.092 | ≤0.091 | —- | —- | —- | |

| PMD Maximum Individual Fiber | ≤0.2 | ≤0.2 | —- | —- | ≤0.11 | ||

| PMD Design Link Value | Ps(nm2*k m) |

≤0.12 | ≤0.08 | —- | —- | —- | |

| Fibre cutoff wavelength λc | nm | ≧ 1180, ≤1330 |

≧1180, ≤1330 |

—- | —- | —- | |

| Cable cutoff wavelength λcc |

nm | ≤1260 | ≤1260 | —- | —- | —- | |

| MFD | 1310nm | um | 9.2+/-0.4 | 9.2+/-0.4 | —- | —- | —- |

| 1550nm | um | 10.4+/-0.8 | 10.4+/-0.8 | —- | —- | —- | |

| Numerical Aperture(NA) |

—- | —- | 0.200+/ -0.015 |

0.275+/-0. 015 |

0.200+/-0 .015 |

||

| Step(mean of bidirectional measurement) |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Irregularities over fiber length and point |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Discontinuity | |||||||

| Difference backscatter coefficient |

dB/km | ≤0.05 | ≤0.03 | ≤0.08 | ≤0.10 | ≤0.08 | |

| Attenuation uniformity | dB/km | ≤0.01 | ≤0.01 | ||||

| Core diameter | um | 50+/-1.0 | 62.5+/-2.5 | 50+/-1.0 | |||

| Cladding diameter | um | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | |

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | |

| Coating diameter | um | 242+/-7 | 242+/-7 | 242+/-7 | 242+/-7 | 242+/-7 | |

| Coating/chaffinch concentrically error |

um | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | |

| Coating non-circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | |

| Core/cladding concentricity error | um | ≤0.6 | ≤0.6 | ≤1.5 | ≤1.5 | ≤1.5 | |

| Curl(radius) | um | ≤4 | ≤4 | —- | —- | —- | |

Package

| 1.Packing material: Wooden drum | |||||||

| 2.Packing length: The standard length of the cable shall be 2 km. Another cable length is also available | |||||||

| if required by the customer |

Cable marking and cable reel marking

The cable sheath shall be marked with white characters according to the customer’s requirement.

Write your message here and send it to us