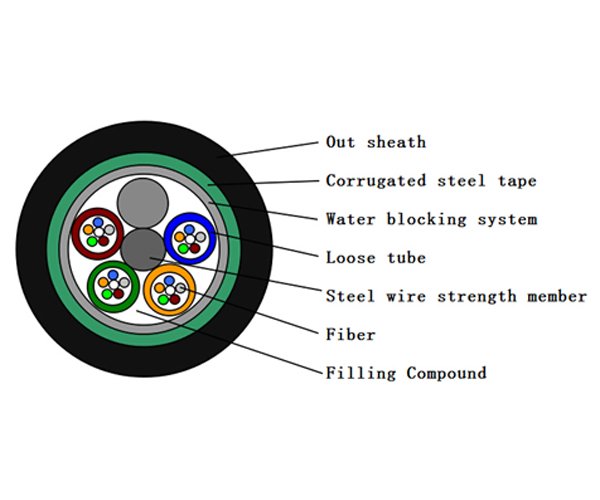

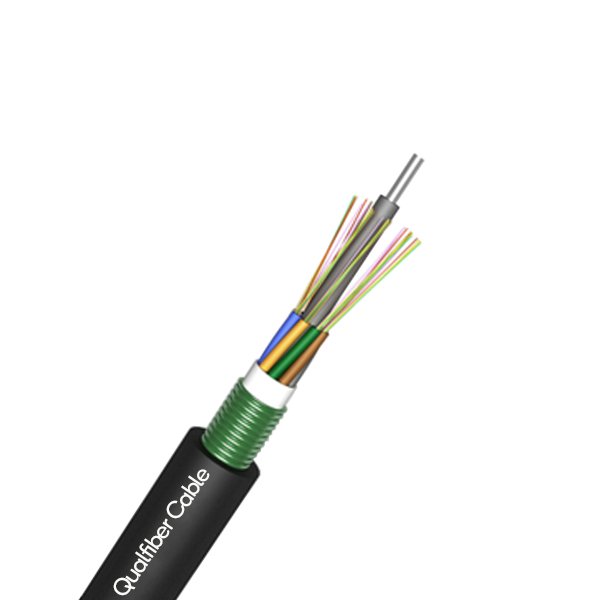

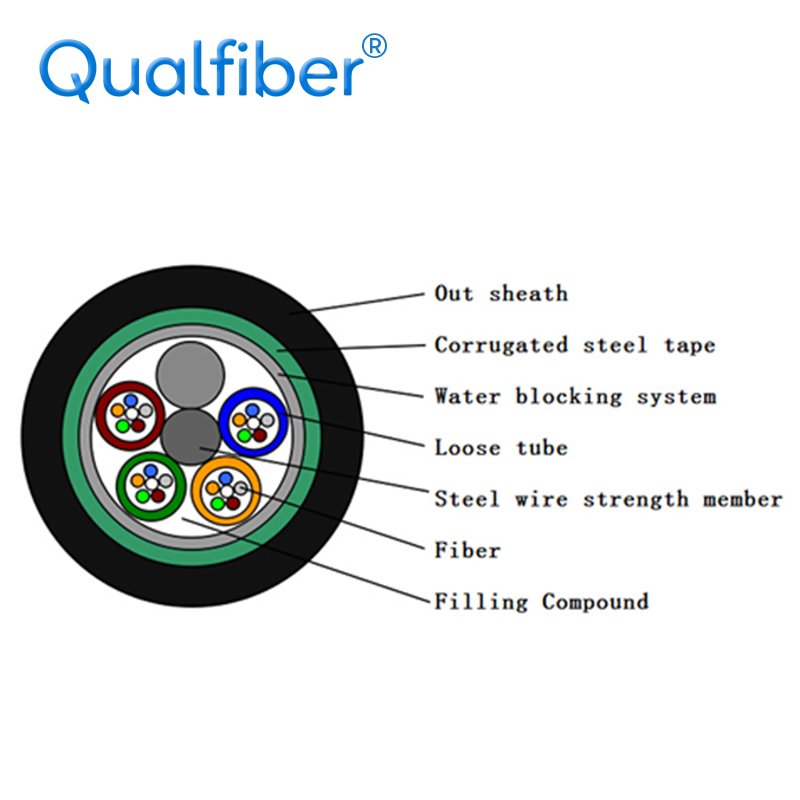

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Color:

Beschreiwung

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Kabele Bau

| Zuel vu Faser | 2~144 F | |||||||

| Fiichtegkeet Barriär | Waasser Blocking System | |||||||

| Zentralstäerkt Member | Matière | Stol Drot / FRP / FRP mat PE Cover | ||||||

| Gréisst | 1.5mm ~ 2.0mm | |||||||

| Loosen Rouer | materiell | PBT | ||||||

| Duerchmiesser | Ф2.2 (baussen / bannen) | |||||||

| Tube-Füllung | Tube Fëllung Verbindung | |||||||

| Rüstung | Matière | Wellblech Stahlband | ||||||

| Aussenhandel | materiell | PE, HDPE | ||||||

| Duerchmiesser | 1,70 ± 0,2 mm | |||||||

Fiber Faarf

| Nee. | 1 | 2 | 3 | 4 | 5 | 6 |

| Faarf |  |

|

|

|

|

|

| Nee. | 7 | 8 | 9 | 10 | 11 | 12 |

| Faarf |  |

|

|

|

|

|

Tube Faarf

| Nee. | 1 | 2 | 3 | 4 | 5 | 6 |

| Faarf |  |

|

|

|

|

|

| Nee. | 7 | 8 | 9 | 10 | 11 | 12 |

| Faarf |  |

|

|

|

|

|

Kabel Mechanesch Charakteristik

| Kär | Kabel Duerchmiesser | Gewiicht | |||||

| 2 Kärelen op 60 Kärelen | 10.0 ± 0.3mm | 115 ± 5 kg / km | |||||

| 72 Kärelen | 10,5 ± 0,3 mm | 120 ± 5 kg / km | |||||

| 96 Kärelen | 12,5 ± 0,3 mm | 180 ± 5 kg / km | |||||

| 144 Kärelen | 14.5 ± 0.3mm | 245 ± 5 kg / km | |||||

| Min Bending Radius (mm) | Laangzäit | 10D | |||||

| Min Bending Radius(mm) |

Kuerzfrësteg | 20D | |||||

| Min Tensile Strength(N) |

Laangzäit | 600 | |||||

| Min Tensile Strength(N) |

Kuerzfrësteg | 1500 | |||||

| Kréien Load (N / 100mm) | Laangzäit | 300 | |||||

| Kréien Load (N / 100mm) | kuerzfrësteg | 1000 | |||||

| Operatioun temperature (℃) |

-40 + 70 ewechzekréien | ||||||

| Installatioun temperature(℃) |

-20 + 60 ewechzekréien | ||||||

Fiber charakteristesch

| Fiber Stil | Eenheet | SM G652 |

SM G652D |

MM 50/125 |

MM 62.5/125 |

MM OM3-300 |

|

| Zoustand | nm | 1310/1550 | 1310/1550 | 850/1300 ewechzekréien | 850/1300 ewechzekréien | 850/1300 ewechzekréien | |

| Dämpfung | dB / km | ≤ | ≤ | ≤ | ≤3.0 / 1.0 | ≤3.0 / 1.0 | |

| 0,36 / 0,23 | 0,34 / 0,22 | 3.0 / 1.0 | —- | —- | |||

| Dispersioun | 1550nm | PS / (nm * km) | —- | ≤18 | —- | —- | Dispersioun |

| 1625nm | PS / (nm * km) | —- | ≤22 | —- | —- | ||

| Bandbreider | 850nm | MHZ.KM | —- | —- | ≧ 400 | ≧ 160 | Bandbreider |

| 1300nm | MHZ.KM | —- | —- | ≧ 800 ewechzekréien | ≧ 500 | ||

| Null Dispersioun Wellelängt | nm | 1300-1324 | ≧ 1302, ≤1322 |

—- | —- | ≧ 1295, ≤1320 |

|

| Null Dispersiounschréiegt | nm | ≤0.092 | ≤0.091 | —- | —- | —- | |

| PMD Maximal individuell Faser | ≤0.2 | ≤0.2 | —- | —- | ≤0.11 | ||

| PMD Design Link Wäert | PS (nm2 * k m) |

≤0.12 | ≤0.08 | —- | —- | —- | |

| Fiber Cutoff Wellenlängt λc | nm | ≧ 1180, ≤1330 |

≧ 1180, ≤1330 |

—- | —- | —- | |

| Kabel Ausschnëtt wavelength λcc |

nm | ≤1260 | ≤1260 | —- | —- | —- | |

| MFD | 1310nm | um | 9,2 +/- 0,4 | 9,2 +/- 0,4 | —- | —- | —- |

| 1550nm | um | 10,4 +/- 0,8 | 10,4 +/- 0,8 | —- | —- | —- | |

| Numeresch Aperture(NA) |

—- | —- | 0.200 + / -0.015 |

0.275 +/- 0. 015 |

0.200 +/- 0 .015 |

||

| Schrëtt (mëttler vun der bidirektionaler measurement) |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Onregelméissegkeeten iwwer Faserlängt length and point |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Diskontinuitéit | |||||||

| Ënnerscheed Réckscatter coefficient |

dB / km | ≤0.05 | ≤0.03 | ≤0.08 | ≤0.10 | ≤0.08 | |

| Eenheet vun Attenuation | dB / km | ≤0,01 | ≤0,01 | ||||

| Kär Duerchmiesser | um | 50 +/- 1.0 | 62,5 +/- 2,5 | 50 +/- 1.0 | |||

| Ëmmantelung Duerchmiesser | um | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | 125,0 +/- 0,1 | |

| Ëmmantelung Net-Circularitéit | % | ≤1,0 | ≤1,0 | ≤1,0 | ≤1,0 | ≤1,0 | |

| Beschichtungsdiameter | um | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | |

| Beschichtung / Chaffinch concentrically error |

um | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | |

| Beschichtung vun Net-Circularitéit | % | ≤6,0 | ≤6,0 | ≤6,0 | ≤6,0 | ≤6,0 | |

| Kär / Ëmmantelungskonzentrationsfehler | um | ≤0.6 | ≤0.6 | ≤1,5 | ≤1,5 | ≤1,5 | |

| Curl (Radius) | um | ≤4 | ≤4 | —- | —- | —- | |

Package

| 1. Verpackungsmaterial: Holztrommel | |||||||

| 2.Verpackungslängt: D'Standardlängt vum Kabel soll 2 km sinn. Eng aner Kabellängt ass och verfügbar | |||||||

| wann vum Client gefrot |

Kabel Marquage an Kabel Reel Marquage

D'Kabelhülse soll mat wäiss Zeechen no dem Ufuerderung vum Client gezeechent ginn.

Write your message here and send it to us