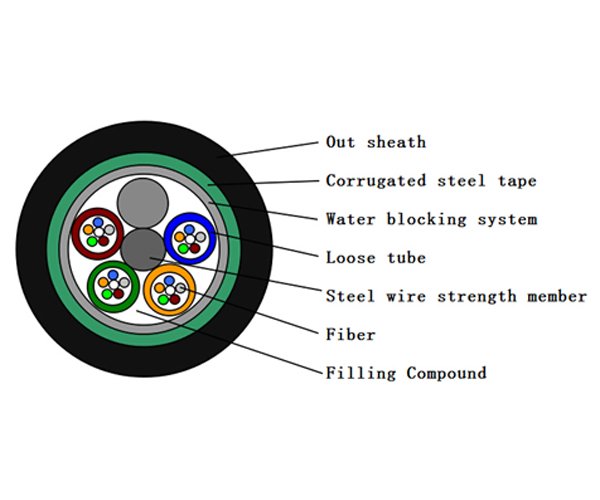

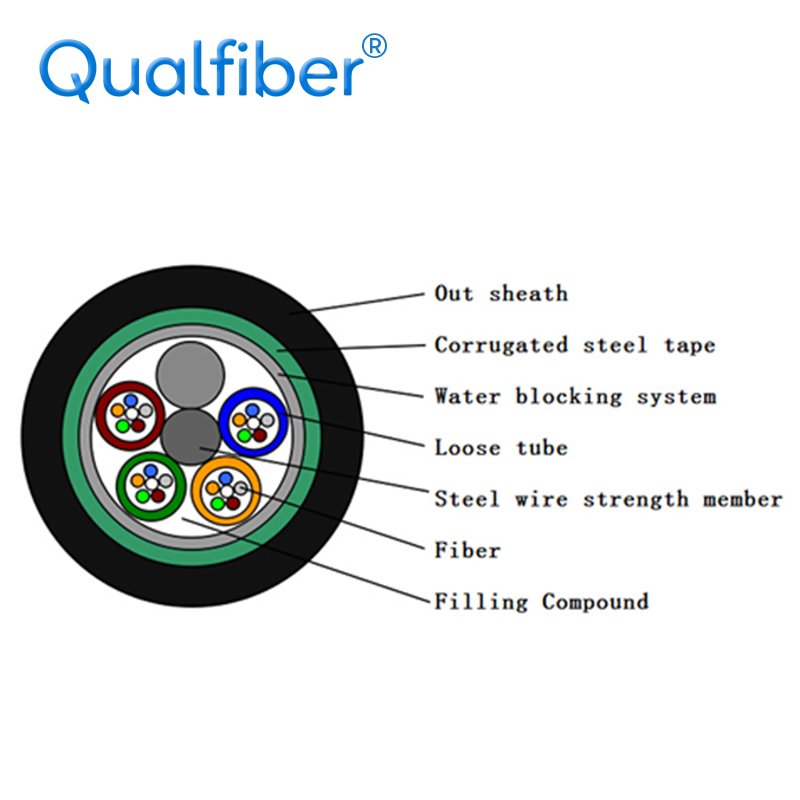

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Color:

Deskrizzjoni

GYTS is a kind of metal strengthening member, loose tube stranded filling type, steel-polyethylene bonded sheathed outdoor optical fiber cable for communication. The structure of the optical cable is made of single-mode or multi-mode optical fiber sheathed by high modulus plastic Fill the loose tube with waterproof compound. The center of the cable core is a metal reinforced core. For some fiber optic cables, the metal reinforced core is also extruded with a layer of polyethylene (PE). The loose tube (and filling rope) is twisted around the central reinforcing core to form a compact and circular cable core, and the gaps in the cable core are filled with water blocking compounds. The steel-plastic composite tape is longitudinally wrapped and then extruded with a polyethylene sheath.

Kostruzzjoni ta 'kejbil

| Numru ta 'fibra | 2~144 F | |||||||

| Barriera ta 'l-Umdità | Sistema tal-imblukkar tal-ilma | |||||||

| Membru tal-qawwa ċentrali | Materjal | Wajer tal-azzar / FRP / FRP b'kisja PE | ||||||

| daqs | 1.5mm ~ 2.0mm | |||||||

| Tubu sfuż | materjal | PBT | ||||||

| Dijametru tal- | Ф2.2 (barra / ġewwa) | |||||||

| Mili tat-tubi | Tubu tal-mili kompost | |||||||

| Armoring | Materjal | Tejp tal-azzar immewweġ | ||||||

| Għant ta 'barra | materjal | PE, HDPE | ||||||

| Dijametru tal- | 1.70 ± 0.2mm | |||||||

Kulur tal-Fibra

| Le. | 1 | 2 | 3 | 4 | 5 | 6 |

| Kulur |  |

|

|

|

|

|

| Le. | 7 | 8 | 9 | 10 | 11 | 12 |

| Kulur |  |

|

|

|

|

|

Kulur tat-Tubu

| Le. | 1 | 2 | 3 | 4 | 5 | 6 |

| Kulur |  |

|

|

|

|

|

| Le. | 7 | 8 | 9 | 10 | 11 | 12 |

| Kulur |  |

|

|

|

|

|

Kejbil Karatteristika mekkanika

| tal-qalba | Dijametru tal-kejbil | piż | |||||

| 2 qlub sa 60 qlub | 10.0 ± 0.3mm | 115 ± 5kg / km | |||||

| 72 qlub | 10.5 ± 0.3mm | 120 ± 5kg / km | |||||

| 96 qlub | 12.5 ± 0.3mm | 180 ± 5kg / km | |||||

| 144 qlub | 14.5 ± 0.3mm | 245 ± 5kg / km | |||||

| Radju tal-Liwi Minimu (mm) | Fit-tul | 10D | |||||

| Liwi Min Radius(mm) |

Għal żmien qasir | 20D | |||||

| Minjiera permessa Tensile Strength(N) |

Fit-tul | 600 | |||||

| Minjiera permessa Tensile Strength(N) |

Għal żmien qasir | 1500 | |||||

| Tgħaffiġ tat-Tgħaffiġ (N / 100mm) | Fit-tul | 300 | |||||

| Tgħaffiġ tat-Tgħaffiġ (N / 100mm) | għal żmien qasir | 1000 | |||||

| Operazzjoni temperature (℃) |

-40 + 70 | ||||||

| Installazzjoni temperature(℃) |

-20 + 60 | ||||||

Fibra karatteristika

| L-istil tal-fibra | Unità | SM G652 |

SM G652D |

MM 50/125 |

MM 62.5/125 |

MM OM3-300 |

|

| kundizzjoni | nm | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| attenwazzjoni | dB / km | ≤ | ≤ | ≤ | ≤3.0 / 1.0 | ≤3.0 / 1.0 | |

| 0.36 / 0.23 | 0.34 / 0.22 | 3.0 / 1.0 | —- | —- | |||

| Dispersjoni | 1550nm | Ps / (nm * km) | —- | ≤18 | —- | —- | Dispersjoni |

| 1625nm | Ps / (nm * km) | —- | ≤22 | —- | —- | ||

| Bandwith | 850nm | MHZ.KM | —- | —- | ≧ 400 | ≧ 160 | Bandwith |

| 1300nm | MHZ.KM | —- | —- | ≧ 800 | ≧ 500 | ||

| Tul ta 'mewġa ta' tixrid żero | nm | 1300-1324 | ≧ 1302, ≤1322 |

—- | —- | ≧ 1295, ≤1320 |

|

| Inklinazzjoni ta 'żero dispersjoni | nm | ≤0.092 | ≤0.091 | —- | —- | —- | |

| Fibra Individwali Massima PMD | ≤0.2 | ≤0.2 | —- | —- | ≤0.11 | ||

| Valur tal-Link tad-Disinn tal-PMD | Ps (nm2 * k m) |

≤0.12 | ≤0.08 | —- | —- | —- | |

| Tul tal-mewġa tal-qtugħ tal-fibra λc | nm | ≧ 1180, ≤1330 |

≧ 1180, ≤1330 |

—- | —- | —- | |

| Cable cutoff wavelength λcc |

nm | ≤1260 | ≤1260 | —- | —- | —- | |

| MFD | 1310nm | um | 9.2 +/- 0.4 | 9.2 +/- 0.4 | —- | —- | —- |

| 1550nm | um | 10.4 +/- 0.8 | 10.4 +/- 0.8 | —- | —- | —- | |

| Numeriku Aperture(NA) |

—- | —- | 0.200 + / -0.015 |

0.275 +/- 0. 015 |

0.200 +/- 0 .015 |

||

| Stadju (medja tal- measurement) |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Irregolaritajiet fuq length and point |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Twaqqif | |||||||

| Differenza backscatter coefficient |

dB / km | ≤0.05 | ≤0.03 | ≤0.08 | ≤0.10 | ≤0.08 | |

| Uniformità tal-attenwazzjoni | dB / km | ≤0.01 | ≤0.01 | ||||

| Dijametru tal-qalba | um | 50 +/- 1.0 | 62.5 +/- 2.5 | 50 +/- 1.0 | |||

| Dijametru tal-kisi | um | 125.0 +/- 0.1 | 125.0 +/- 0.1 | 125.0 +/- 0.1 | 125.0 +/- 0.1 | 125.0 +/- 0.1 | |

| Kisi tal-kisja mhux ċirkolarità | % | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | |

| Dijametru tal-kisi | um | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | 242 +/- 7 | |

| Coating/chaffinch concentrically error |

um | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | |

| Kisi ta 'nonċirkolarità | % | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | |

| Żball tal-qalba / kisi tal-konċentriċità | um | ≤0.6 | ≤0.6 | ≤1.5 | ≤1.5 | ≤1.5 | |

| Curl (raġġ) | um | ≤4 | ≤4 | —- | —- | —- | |

Pakkett

| 1.Pakkjar tal-materjal: tanbur tal-injam | |||||||

| 2. It-tul tal-ippakkjar: It-tul standard tal-kejbil għandu jkun ta '2 km. Tul tal-kejbil ieħor huwa wkoll disponibbli | |||||||

| jekk meħtieġ mill-klijent |

Immarkar tal-kejbil u mmarkar tar-rukkell tal-kejbil

Il-għant tal-kejbil għandu jkun immarkat b'karattri bojod skont il-ħtieġa tal-klijent.

Write your message here and send it to us