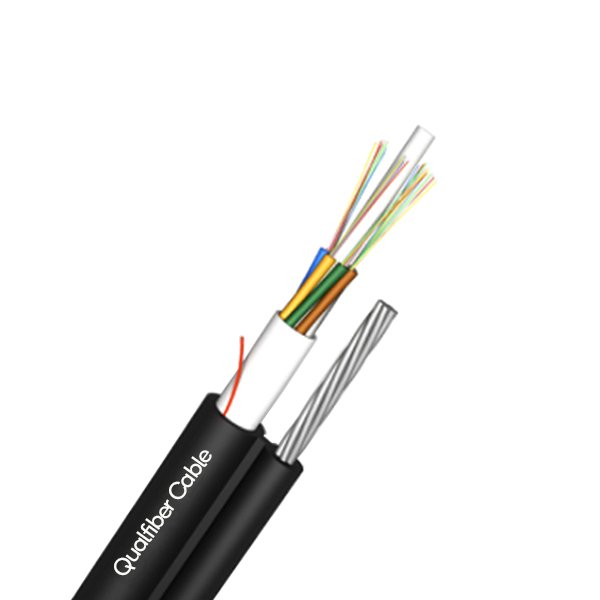

The structure of GYFTC8Y optical cable is to sleeve the optical fiber into the PBT loose tube, and the loose tube is filled with waterproof compound. The center of the cable core is a non-metallic reinforced core, and the loose tube (and filler rope) is twisted around the central reinforced core to form a compact and circular cable core. The cable core and the steel wire strands are integrated into a figure-8 polyethylene sheath

Color:

Description

Cable structure

Technical data

Technical data

| No. of cable | 4 | 8 | 12 | 24 | 48 | 72 | 144 | ||||

| Fiber Model | G.652D | ||||||||||

| Design(StrengthMember+Tube&Filler) | 1+5 | 1+6 | 1+12 | ||||||||

| Central Strength Member | Material | FRP | |||||||||

| Diameter(±0.05)mm | 1.5 | 2.1 | |||||||||

| Loose Tube | Material | PBT | |||||||||

| Diameter(±0.06)mm | 1.8 | 2.1 | |||||||||

| Thickness(±0.03)mm | 0.32 | 0.35 | |||||||||

| The Max.Core NO./Tube | 4 | 6 | 12 | ||||||||

| Filler Rope | Material | LDPE | |||||||||

| Colour | White | ||||||||||

| Diameter(±0.06)mm | 1.8 | 2.1 | |||||||||

| Water Blocking layer(Material) | Flooding Compound | ||||||||||

| Support pieces | Material | Galvanized steel strand | |||||||||

| Size | 0.9×7 | 1.0×7 | |||||||||

| Web | Material | MDPE | |||||||||

| Size(±0.2)mm | 2.5×3 | ||||||||||

| Outer Sheath① | Material | MDPE | |||||||||

| Thickness(±0.2)mm | 1.5 | ||||||||||

| Outer Sheath② | Material | MDPE | |||||||||

| Thickness(±0.2)mm | 1.8 | ||||||||||

| Cable Diameter(W×H) (±0.2)mm | 8.5×16.6 | 9.1×17.0 | 9.7×18.1 | 13.8×22.2 | |||||||

| Cable Wetght(±10)kg/km | 120 | 132 | 150 | 235 | |||||||

| Min. bending radius | Without Tension | 10.0×Cable-φ | |||||||||

| Under Maximum Tension | 20.0×Cable-φ | ||||||||||

| Temperature range (℃) |

Installation | -20~+60 | |||||||||

| Transport&Storage | -40~+70 | ||||||||||

| Operation | -40~+70 | ||||||||||

Fiber Color

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color |  |

|

|

|

|

|

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color |  |

|

|

|

|

|

Tube Color

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color |  |

|

|

|

|

|

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color |  |

|

|

|

|

|

The properties of single-mode optical fiber (ITU-T Rec. G.652.D)

| Item | Specification |

| Fiber type | Single-mode |

| Fiber material | Doped silica |

| Attenuation coefficient @ 1310 nm @ 1383 nm @ 1550 nm @ 1625 nm |

£ 0.36 dB/km £ 0.32 dB/km £ 0.22 dB/km £ 0.30 dB/km |

| Point discontinuity | £ 0.05 dB |

| Cable cut-off wavelength | £ 1260 nm |

| Zero-dispersion wavelength | 1300 ~ 1324 nm |

| Zero-dispersion slope | £ 0.092 ps/(nm2.km) |

| PMDQ (Quadrature average*) | £0.2 ps/km1/2 |

| Mode field diameter @ 1310 nm | 9.2±0.4 um |

| Core / Clad concentricity error | £ 0.5 um |

| Cladding diameter | 125.0 ± 0.7 um |

| Cladding non-circularity | £1.0% |

| Primary coating diameter | 245 ± 10 um |

| Proof test level | 100 kpsi (=0.69 Gpa), 1% |

| Temperature dependence 0oC~ +70oC @ 1310 & 1550nm |

£ 0.1 dB/km |

Application:

| NO. | Item | Requirement | |

| 1 | Allowable Tensile Strength | Short Term | 2700 N |

| Long Term | 1000 N | ||

| 2 | Allowable Crush Resistance | Short Term | 1000 (/100mm) |

| Long Term | 300 (/100mm) | ||

Sheath marking

The color of marking is white, but if the remarking is necessary, the white color marking shall be printed newly in a different position.

An occasional unclear of length marking is permitted if both of the neighboring markings are clear.

Both cable ends are sealed with heat shrinkable end caps to prevent water ingress.

Write your message here and send it to us